| MENU |

|---|

Equipment Product

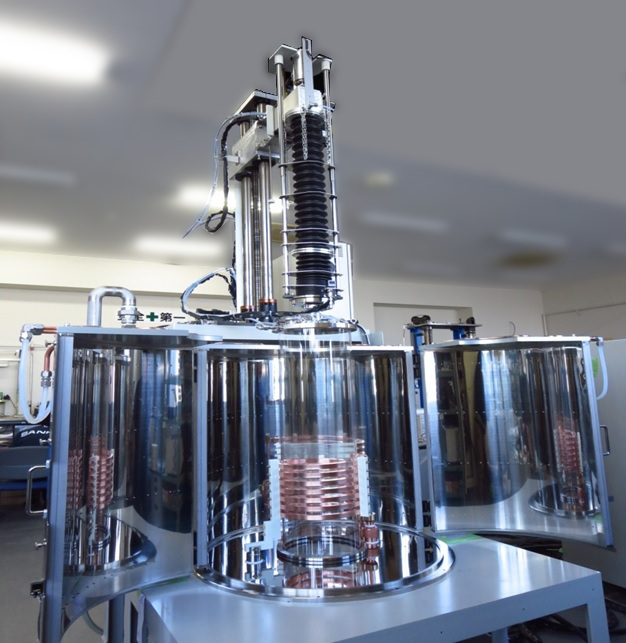

Crystal growth furnace

CZ single crystal growth equipment with RF heating system.

Characteristics

| Temperature | Max:2,000℃ |

|---|---|

| Heating system | RF induction heating |

| Chamber | Quartz type |

Specifications

Driving system

| Pulling speed | Precise

speed range: 0.1-10mm/hr Rough speed range: 2-300mm/min (Movable distance: 600mm) |

|---|---|

| Rotation rate | 0.3-60rpm |

| Work-coil speed | Precise

speed range: 0.1-10mm/hr Rough speed range: 2-300mm/min (Movable distance: 100mm) |

| Load cell | 20kg(typical) |

RF generator

| Output | 40kW(work-coil only) |

|---|---|

| Frequency | Fixed from 5 to 9.9kHz |

| Power supply | 3Φ200V±10% 50/60Hz |

Typical outer size

| Main chamber | W 1,450 D 1,450 H 3,190 |

|---|---|

| Controller | W 850 D 1,030 H 1,792 |

| RF generator | W 430 D 810 H 800 |

| Matching trans box | W 676 D 1,090 H 675 |

Skull melt furnace with RF heating system

RF induction heating skull melt furnace.

Characteristics

Equipment to grow oxide-crystals without Iridium or other metal crucibles.

By realizing the rare metal free process, the growth cost can be dramatically deceased.

And it can grow crystals with very high melting temperature under any gas atmospheres because we do not need to care about the crucible.

Annealing furnace

SANKO has full customized annealing furnace lineups at lower price.

e.g.)Furnace with a wide effective area under high temperature is realized by using

MoSi2 heaters placed in entire sidewalls.

Characteristics

- We produce the annealing furnace with a workstage elevating system. Compared with a front-door-opening type, a small footprint, a wide homogenized temperature distribution and a low contamination can be realized.

- Under air atmosphere, maximum temperature of 1,800℃ can be achieved by using MoSi2 heater elements.

- By using workstage elevating and sliding system, safe and easy work-setting is available.

- Temperature controller has 19 programs and each program has 19 steps.

- System condition can be checked by monitoring of the heater current and voltage.

- Color touch LED display panel is installed and it performs user-friendly operation.

- Safe operation is available by the interlock system, such as over-heating and an over-current protection.

Specifications

Furnace size

Available to customize the furnace to customer’s requests.

Footprint

Minimum 340x340mm~

| A wide variety of furnace can be realized such as a front-door-opening type and a workstage-elevating type. Optionally, work slide structure can be installed in the work elevation system. |

| Large size |

Middle size |

Small size |

||

|---|---|---|---|---|

| Resistive heating system |

Heater material |

MoSi2 |

MoSi2 |

MoSi2 |

| Installation of heater |

Placed heaters in entire sidewalls |

Placed heaters in entire sidewalls |

Placed heaters in entire sidewalls |

|

| Inner size |

W1,030 D1,030 H530 | W730 D730 H550 | W380 D380 H430 | |

| Homogenized temperature area |

W1,000 D1,000 H480 | W680 D680 H550 | W340 D340 H400 | |

| Power consumption |

80kVA | 45kVA | 35kVA | |

| Temperature controller |

Renge of temperature |

0.00~1,700.0℃ | 0.00~1,700.0℃ | 0.00~1,700.0℃ |

| Temperature sensor |

B-type thermo couples |

B-type thermo couples |

B-type thermo couples |

|

| Resolution |

0.1℃ | 0.1℃ | 0.1℃ | |

| Programs and steps |

19programs(19 steps each) |

19programs(19 steps each) |

19programs(19 steps each) |

|

| Work elevating system |

Maximum load |

2,000kg | 2,000kg | 1,000kg |

| Effective area |

W:1,000mm D:1,000mm | W:680mm L:680mm | W:340mm L:340mm | |

| Outer size |

W 1,700mm D 2,080mm H 2,600mm |

W 1,480mm D 1,985mm H 2,310mm |

W 1,100mm D 1,590mm H 2,260mm |

|

High-temperature resistive heating furnace operating under vacuum or inert gas atmosphere

This resistive heating furnace has graphite heater units and a sample transferring unit, and it is operated at high temperature under inert gas atmosphere for material synthesis.

Characteristics

- The furnace is composed of upper and lower chambers and synthesizes materials effectively.

- High-efficiency resistive heating can achieve a maximum temperature of 1,800℃.

- Color touch LED display panel is installed and it performs user-friendly operation.

- TC monitor data can be logged and available to output in a CSV format.

- The work can be easily and safely set by this elevating system.

- Auto operation is available by using a recipe control of heater temperature, valves and MFCs.

Vertical resistive heating Bridgman furnace

This equipment heats the inside of an alumina tube to a high temperature under an inert or oxidizing gas atmosphere. An internal crucible is moved and crystals are grown by unidirectional solidification.

Characteristics

- “Vertical” resistive heating system can reduce air contaminations and realize a small footprint.

- MoSi2 heater realizes typical temperature of 1,800℃(max: 1,830℃)under inert or oxygen gas atmosphere.

- Crucible elevating system has a seamless axis-speed control from precise to coarse.

- Crucible can be easily and safely set by this elevating system.

- Crucible and thermocouples(TCs)can rotate in a desired speed.

- TC monitor data can be logged and available to output in a CSV format.

- System condition can be checked by monitoring of the heater current and voltage.

- “Shutter” on the furnace keeps the temperature constant.

- Color touch LED display panel is installed and it performs user-friendly operation.

- Auto power control operation(0-100%)is available by operating recipes.

- Optionally, auto valve control and MFC operation is available.

HOT N2 gas supplier

High temperature and High purity N2 gas can be supplied. Temperature(max:400℃)can be controlled and it contains a failsafe system.

HOT N2 heater specification

| Heater Specifications | Single phase AC200V 900W | Single phase AC200V 1800W |

|---|---|---|

| N2flow rate | 150SLM | 300SLM |

| Normal gas temperature | 150°C | 200°C |

| Flow rate | 200L/min or less |

|---|---|

| Output | Single phase AC200V 1kW |

| Temperature range | 400℃ or less |

| Pressure range | 0.5MPa or less |

| Outer size | φ90mm×395mm(a joint part except) |

| Connection | IN/OUT 3/8 Swagelok |

| Material and shape of theheating wire | KANTHAL APM / Wave type heating element |

| Body material | SUS304 |

| GAS TEMP: thermo couple for the control system | One pair of K type thermo couple (including 3m compensating lead wires) |

| HEATER TEMP: thermo couple for the over-heating safe system | One pair of K type thermo couple (including 3m compensating lead wires) Please set the temperature below 600℃. |

TAPE HEATER CONTROLLER specification

| Temperature Controller | Normal | Expansion |

|---|---|---|

| Number of channels | 1ch | 4ch (max.

20ch by request) |

| Interlock | Over-temperature, low flow, etc. | Over-temperature, low flow, etc. |

| Temperature setting | Digital or analog | Digital or analog |

| number of channels | 1ch |

|---|---|

| Outer size | W:350mm×H:140mm×D:242mm |

| Temperature range | 0〜50℃(no condensing) |

| Temperature indicator | Two indicators for GAS TEMP and HEATER TEMP |

| Control type | SSR control |

| Load | Single phase AC200V 10A |

| Input power source | Single phase AC200V±10% |

| Thermo couple | K type thermo couple |

| External input | Low flow signals, external input signals |

| Input and output connectors | One set (including 3m cable) |

| Power supply connection | M5 terminal box |

| External output connection | M4 terminal box. A contact. (including 3mcable) |

| Color | Mansel N3 |

| Breaker | 15A |

| Item | Connection place | Remarks |

|---|---|---|

| Power supply input terminal | TB1-1,2,3 | Single phase AC200V 1KVA with a ground connection |

| Heater output terminal | TB2-1,2 | 10A MAX |

| GAS TEMP thermo couple | TB3-1,2 | K type thermo couple |

| HEATER TEMP thermo couple | TB3-3,4 | K type thermo couple |

| FL low flow signal | TB4-1,2 | “Open” at low flow (the temperature is preset to 50℃) |

| External input signal | TB4-3,4 | “Open” at abnormal and emergency (Output is automatically stopped) |

| Input and output connectors | J1-1,2 | Alarmed at “Open”. |

| J1-3,4 | Output is stopped at “Open”. | |

| J1-5,6 | When GAS TEMP temperature reached to lower or upper limit, the contact becomes “Open”. | |

| J1-7,8 | When GAS TEMP temperature reached to upper limit, the contact becomes “Open” and output is automatically stopped. | |

| J1-9,10 | When HEATER TEMP temperature reached to lower or upper limit, the contact becomes “Open”. | |

| J1-10,11 | When HEATER TEMP temperature reached to upper limit, the contact become “Open” and output is automatically stopped. | |

| J1-12,13 | When HEATER TEMP temperature reached to upper limit, the contact become “Open” and output is automatically stopped. |

Safety specification

| Over-current detection 2 | The circuit protector 15A is installed in a temp. cont. heater line. |

|---|---|

| Upper and lower limit alarm (GAS TEMP) | Preset value 240 Alarmed when the temperature is out of 100℃±50℃. |

| Upper and lower limit alarm (HEATER TEMP) | Preset value 500 Alarmed when the temperature is out of 250℃±50℃. |

| Temperature overheat alarm (GAS TEMP) | Preset value 260 Alarmed when the temperature becomes over 120℃. |

| Temperature overheat alarm (HEATER TEMP) | Preset value 580 Alarmed when the temperature becomes over 250℃. |

Low N2 flow detection | The temperature of the control unit changes into “50℃”. |

Tape Heater

Easy desorption

This tape heater can be set easily and realizes uniform temperature.

Specification

| Quality of the material | PTFE |

|---|---|

| Work | 1/4 inch SUS piping |

| Outside dimension | 750mm[ in length]×45mm in width |

| Electric specification | 200ohm±10%(AC100V 50W) |

| The maximum connectivity number | Five(750mm×5) |

| Safety | 150℃ thermo switch built-in |

Control Unit

Jig unit to automate temperature control, flow control, etc.